Climate change is challenging several fields including the agriculture sector. The higher temperatures and the consequent weather events facilitated the distribution of exotic organisms in environments where they were previously unknown. In addition to their introduction into new areas, their virulence to the host is increased due to optimal climatic conditions. Due to the above, agri-food products in the Mediterranean suffer from an inadequate logistics infrastructure and a basic low standard of safety, quality and tracking. Low standards of innovation and management make it difficult for companies to satisfy consumer demands. This also makes local products uncompetitive compared to imported ones, creating a dependence on international markets. A sustainable and safe food transformation, including the adoption of a healthy Mediterranean diet, could increase the competitiveness of local products and create new business opportunities.

The Partnership on Research and Innovation in the Mediterranean Area (PRIMA), partly financed by the EU research and innovation programme Horizon 2020, has supported a project to increase efficiency, sustainability and competitiveness in the post-harvest citrus process chain in the Mediterranean regions.

The BiOrangePack project involves five major citrus-producing countries of the Mediterranean region, including the two main citrus-producing EU-countries (Italy and Spain), the two major citrus exporters (Spain and Turkey), two North-African dynamics and expanding citrus producers (Algeria and Tunisia) the leading EU-country producing organic citrus fruits (Italy) as well as the main importer EU-country of citrus fruit (France). This project is coordinated by the University of Catania (Italy) and involves 14 universities and research centres from 6 Mediterranean countries. Each partner has a well-defined role based on their detailed expertise and knowledge. The overall objective of the project is to increase the efficiency, sustainability and competitiveness of the post-farming processing chain of organic citrus fruit, by intervening on points of weakness and the unresolved problems of this supply chain. Consistently with the scope, specific objectives include:

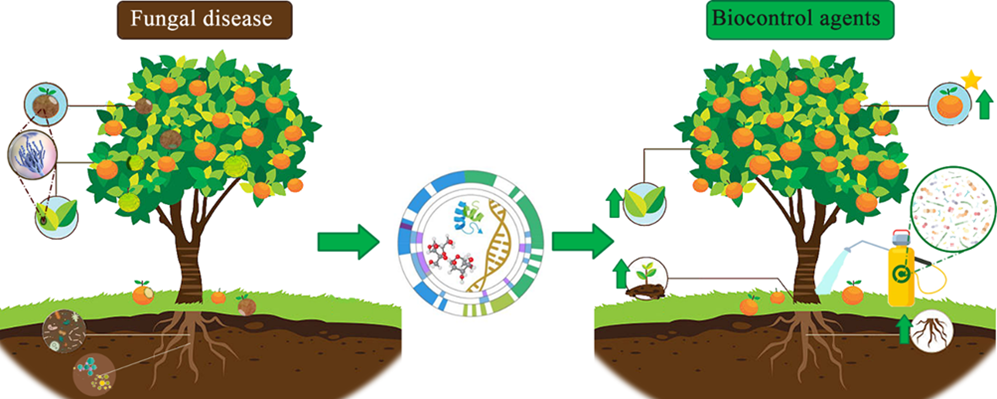

i) Reduction of losses caused by post-harvest rots during storage and transportation, by treating the fruits with non-toxic, eco-friendly substances and bio-products compatible with organic food as an alternative option to synthetic fungicides (innovative green technology). The goal is to reduce the losses from 30 to 0.5%.

ii) Use of molecular diagnostics to raising of the quality standards of fresh fruits and juice (innovative biotechnology) for the detection of pathogenic quarantine fungi and mycotoxins (under detectable levels) and excluding fruits that do not comply with EU and EPPO phytopathological and toxicological standards;

iii) extending fruit shelf life by at least 10 days, using bio-active coatings that are easy to use and biodegradable;

iv) application of smart technologies (ICT-based technologies and machine learning techniques) to improve the efficiency of shipping times and optimize the delivery of fruits to the targeted markets (20% increase in shipment efficiency and exclusion of complaints or cuts);

v) reduction up to 80% of the waste of the industrial fruit transformation by recycling and exploiting the most of citrus pulp, the major by-product of juice and essence industry, by utilizing it as a raw material to produce a biodegradable and natural biocoating of fruit packaging, in accordance with the principles of circular economy and the standards of organic food.

Conclusion

Several phytosanitary products have been demonstrated to be effective against some postharvest fungal pathogens of fruit and vegetables, but only a selected number of biological products are commercially available to control post-harvest citrus diseases. Recently, new molecular diagnostic techniques in situ have been developed for the detection of pathogens in plant tissues and for the analysis of mycotoxin compounds on fruit, but none of these methods have been applied for the routine detection of citrus quarantine fungal pathogens. Bioactive organic materials have been widely used for food packaging, but there are still no packaging products that can extend the shelf-life of citrus fruit from shipping to sale. Neither is available yet as an integrated approach specifically designed for the post-harvest processing chain of organic citrus fruit, based on the use of environmentally friendly fungicides, biocontrol agents and innovative activated packaging together with improved fruit storage and transport logistics.